Work fields

Work fields

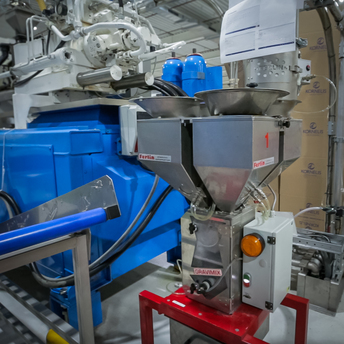

Blow molding, injection molding and extrusion

We supply machines to customers who process plastics, thereby ensuring, among other things, the reduction of waste and costs, efficient resource management and process optimization in plastics processing.

The three main forms of plastic processing are blow molding, injection molding and extrusion. Ferlin supplies machines for all these methods. Read more below about how these methods work and how our customers apply Ferlin machines in their plastic production process.

Field of work

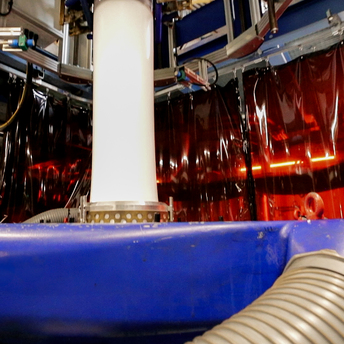

Blow molding

Blow molding is a widely used technique in plastic processing for manufacturing hollow plastic products. This process is often used to make items such as bottles, tanks, and other hollow objects.

During the process, molten plastic is made into a tube shape (parison), which is placed in a mold. Air is then blown into the tube, pressing the material against the walls of the mold and cooling it to the desired shape. Once the plastic has hardened, the mold is opened, and the finished product is taken out. This process is ideal for producing lightweight, strong and complex shapes.

Curious about what Ferlin can specifically contribute to optimize your blow mold process? Get in touch and schedule an appointment with one of our sales engineers. They will be happy to advise in improving your process.

Field of work

injection molding

Injection molding is a technique in plastics processing in which molten plastic is injected into a mold under high pressure. The plastic fills the mold and then cools, hardening and taking the shape of the mold. Once the material has cooled and cured, the mold is opened, and the finished product is ejected. This technique is great for making precise and complex parts, such as toys, housings and car parts.

Curious about what Ferlin can specifically contribute to optimize your injection molding process? Get in touch and schedule an appointment with one of our sales engineers. They will be happy to advise in improving your process.

Field of work

Extruding

Extruding is a plastic processing technique in which molten plastic is pushed through a special mold to make long, continuous products such as pipes, sheets, or profiles. The plastic is heated until it melts, then pressed through an opening (die) to form the desired shape. It then cools and is cut to the desired length.

Curious about what Ferlin can specifically contribute to optimize your extrusion process? Get in touch and schedule an appointment with one of our sales engineers. They will be happy to advise in improving your process.

Contact Ferlin